Ray Mistry

Chief Technology Officer

Project Canary completed an extended METEC testing over 3 weeks, September 19 through October 9, 2022, to further validate and improve our Quantification Version 2 Algorithm used to calculate total site emissions (kg/hr). This was our longest contiguous testing and yielded promising results for current and future iterations of the Canary Quantification Algorithm, with a 1% error on cumulative emission quantification over the 3 weeks.

The extended test period, in conjunction with variably higher rates, up to 2 grams per second, required procurement of a third-party compressed natural gas trailer to ensure gas was available throughout the testing period with minimal downtime. The testing was conducted by simulating baseline emissions of a facility represented by two persistent low emissions. Adjusting for the baselines when determining a leak demonstrated strong performance in the MTTD (mean time-to-detection) as we experimented with higher concentrations of leaks. MTTD is important because if we detect leaks quickly, we can distinguish between small leaks that are sequential versus signaling a single, prolonged leak.

The METEC location with corresponding possible leak points is shown in the image below (Fig. 01) and is defined in the following groups: tanks, wells, separators, and flares. We installed three Canary X devices around the facility’s perimeter to detect emissions.

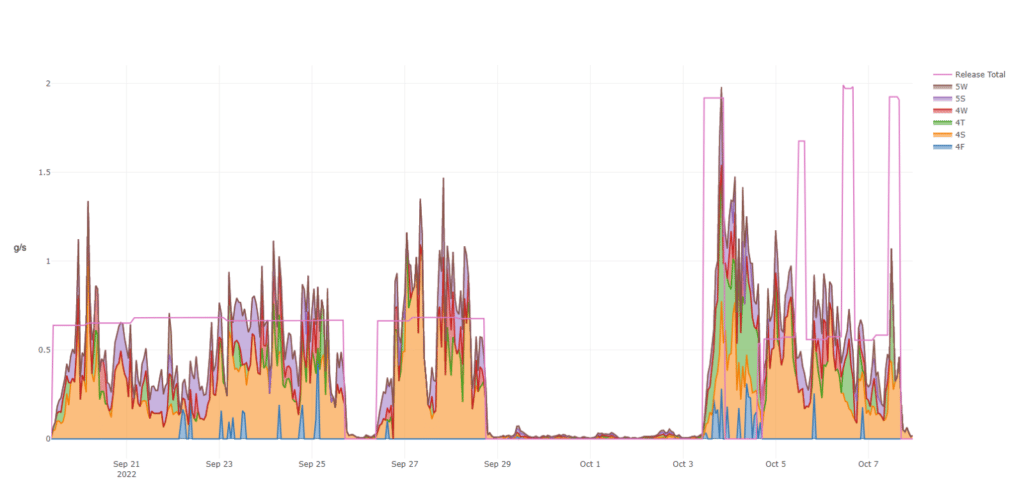

As shown in Figure: 02 below, we observed fast reactions to higher emission releases (pink line), with the density of spikes on the graph indicating high accuracy of MTTD. The aggregate grams/second for each time period represents the total site emissions quantified by Project Canary relative to the emissions releases. The colors on the chart correlate with equipment groups to attribute emissions to sources.

The graph illustrates the changes to gas releases in the 3rd and final week of testing. While we continued to release multiple low persistent baseline emissions, we added large fugitive emissions to simulate an unexpected leak from a piece of equipment on a facility. Our rolling average quantification algorithm results in a small flattening of the release peaks and extension of the tail, for aggregate quantification over the period that closely matched the total gas released.

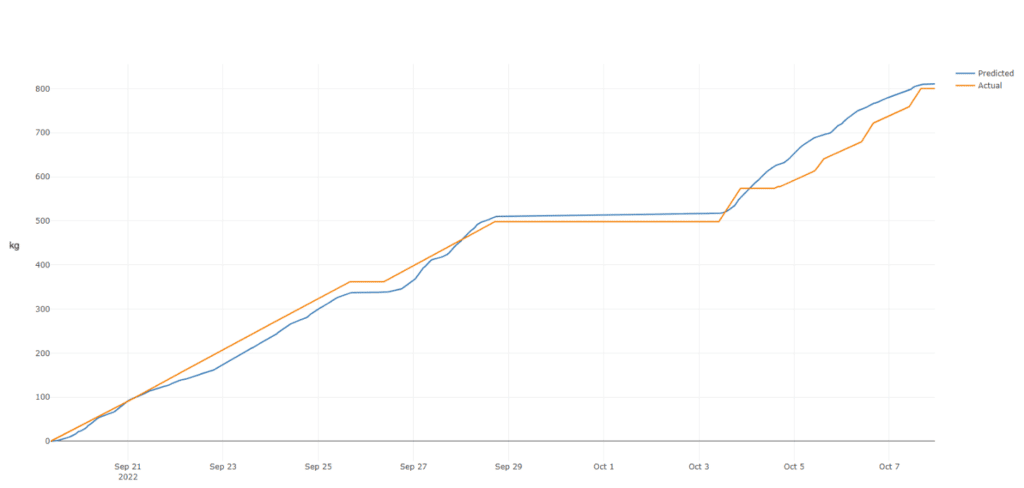

Initial observations are that the error for our total quantified mass of methane emitted is just over 1% (810.8 kg predicted vs. 800.3 kg actual). While this result may not be representative of every pad’s result, we assume that METEC’s facilities offer a reasonable comparison to a real-world wellpad.

Quantifying emissions is an iterative development process. We continue to improve our algorithms for more complex pad and equipment structures. Therefore, we will be testing with ADED at METEC again in February 2023, as well as doing ADED testing in Q1 2023 for an operator at a field location. After each test, we finalize the analysis, compile results and publish findings.